![]() Windy.

Windy.

WeChat

WeChat

WhatsApp

WhatsApp

Click:342 seen

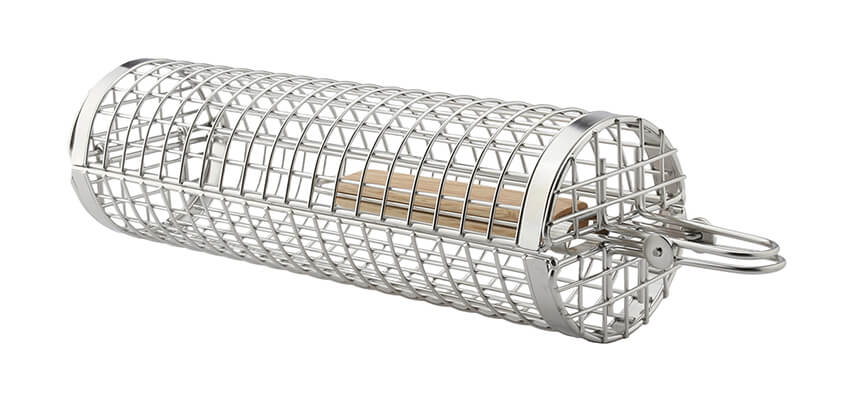

The cylindrical oven suitable for charcoal is a specialized equipment that uses charcoal as the heat source or processing material. Its function combines the characteristics of charcoal with the advantages of the rotating drum. It is mainly used in food baking, industrial heating, and charcoal processing, etc. The specific functions are as follows:

The baking function using charcoal as the heat source (food processing and catering scenarios)

Utilize the hot fire of charcoal and far-infrared heating to achieve characteristic baking

1. When charcoal burns, the fire and far-infrared radiation can quickly penetrate the surface of the ingredients, forming a crispy crust (such as the "Maillard reaction" in grilled meat), while retaining the internal moisture, giving the food a unique charcoal-flavored taste, which is difficult to be replaced by electric or gas grills.

2. The rotation of the drum can make the ingredients (such as meat, seafood, vegetables) evenly contact the charcoal heat source, avoiding local burning, and at the same time, allowing the oil to drip onto the charcoal to produce smoke, increasing the smoky aroma of the food (such as grilled chicken wings, grilled lamb chops).

Precise control of temperature and heat

By adjusting the thickness of the charcoal layer inside the drum, the ventilation volume (such as the design of the air intake of the furnace body) and the rotation speed, the baking temperature can be flexibly controlled.

High-temperature quick baking: Suitable for ingredients that need a crispy outside and tender inside (such as grilled steak), the drum rotation can quickly lock in the meat juice;

Low-temperature slow baking: Suitable for marinated meat or large ingredients (such as a whole grilled pig), the continuous and stable heat of the charcoal through the drum rotation is evenly transmitted, avoiding the burning of the outer skin while the inside is not yet cooked.

Efficient baking for outdoor and commercial scenarios

1. Mobile charcoal cylindrical oven (such as street sausage carts, barbecue stall equipment) is convenient for on-site operation. The drum rotation can simultaneously bake a large amount of ingredients, meeting the demand during peak customer flow;

2. Some commercial ovens are equipped with insulation layers and exhaust systems, which can reduce the loss of charcoal heat and handle the smoke, meeting environmental protection requirements (such as charcoal pizza ovens in shopping malls' dining areas).

Processing function using charcoal as the processing object (industrial and energy fields)

Regeneration and activation treatment of charcoal

1. In the field of environmental protection, the cylindrical oven can be used for the regeneration of waste charcoal: Through high-temperature baking (with or without specific gas introduction) to remove impurities (such as oil stains, pigments) adsorbed on the surface of the charcoal, restoring its adsorption capacity, and achieving the repeated use of activated carbon (such as for water treatment, air purification carbon) (e.g., charcoal pizza ovens in shopping mall dining areas).

2. Some cylindrical ovens can be used for the activation process of charcoal: Introducing water vapor or carbon dioxide, reacting with the charcoal at high temperatures, expanding the internal pore structure and enhancing the adsorption performance of activated carbon (such as in industrial activated carbon production).

Drying and modification treatment of charcoal

1. If the moisture content of the charcoal is too high (such as being damp), the cylindrical oven can remove the moisture through low-temperature baking (50-100°C) to ensure its combustion efficiency, often used for pre-treatment before storage of charcoal;

2. In the chemical field, the surface modification of charcoal can be carried out through spraying catalysts or immersing in chemical reagents, then drying and solidifying, making it suitable for specific catalytic reactions (such as in gas purification, chemical synthesis) (e.g., charcoal ovens for pizza in shopping mall dining areas).

Mixing processing of charcoal with other materials

The rotating characteristics of the drum oven can be used for the uniform mixing and heating treatment of charcoal with other materials, for example:

1. After baking the mixture of charcoal and coal powder, the fuel combustion performance can be improved, used in industrial boilers;

2. After high-temperature baking of the mixture of charcoal and mineral powder, it can be used as a reducing agent in metallurgical reactions (such as in the iron smelting process, carbon reduction) (e.g., charcoal ovens for pizza in shopping mall dining areas).

Advantages of equipment design and heat source characteristics

Energy-saving and cost advantages of charcoal combustion

1. Charcoal as a heat source is relatively low in cost (especially in regions with abundant wood resources), and the combustion efficiency is stable, suitable for baking scenarios with low temperature precision requirements (such as catering, small-scale food processing);

2. The insulation design of the drum oven can reduce the amount of charcoal used, extend the burning time, and lower the usage cost.

Flexible adaptation to different types of charcoal

1. It can be compatible with various types of charcoal, such as mechanism charcoal (high density, long burning time), fruitwood charcoal (strong aroma), and bamboo charcoal (high temperature and durable burning). Based on the requirements, choose the appropriate type of charcoal to adjust the baking effect or processing purpose.

Environmental protection and operational convenience

1. Some drum-type ovens are equipped with an exhaust smoke filtration system, which can reduce the smoke dust generated by charcoal combustion (such as commercial equipment), meeting environmental protection standards;

2. The automatic rotation design of the drum reduces the workload of manual turning of ingredients or materials, especially suitable for batch production or long-term outdoor use.

Typical application examples

| Domain | Application scenarios | Effect |

| Food and Barbecue | Korean barbecue, Brazilian barbecue | Using charcoal fire and the rotation of the drum to achieve uniform baking, and infusing the aroma of charcoal fire |

| food processing | Charcoal-grilled sausages, fruitwood-roasted duck | Using charcoal fire and the rotation of the drum to achieve uniform baking, adding the aroma of charcoal fire, controlling the heat to make the crust crispy and the interior juicy, enhancing the flavor of the product. |

| Environmental protection industry | Recovery of used activated carbon | High-temperature baking removes impurities and restores the adsorption capacity. |

| Energy processing | Combination of charcoal and biomass as fuel | The drum rotates to mix the materials and heat them, thereby enhancing the efficiency of fuel combustion. |

Summary

The cylindrical charcoal oven suitable for cooking not only takes advantage of the unique flavor and heating characteristics of charcoal as a heat source, but also achieves the uniformity of food cooking and the efficiency of material processing through the rotation of the cylinder. It not only provides distinctive charcoal-fired cuisine in the dining scene, but also undertakes functions such as charcoal regeneration, modification, and mixed processing in the industrial field. It is a practical tool that combines traditional heat sources with modern equipment design.